eVTOL manufacturer Archer Aviation plans to capitalize on the products developed by Palantir Technologies Inc. (NASDAQ: PLTR) in order to streamline and increase efficiency at its two manufacturing plants, one known as “ARC” in Covington, Georgia, and the “Integrated Test Lab and Manufacturing Facilities” in San Jose, California. It is expected that the Covington, GA plant will produce around 650 aircraft annually by 2030, which would make it one of the largest aircraft manufacturing plants by volume. The San Jose plant will produce the initial Midnight eVTOL aircraft, as well as the batteries to power the electric aircraft.

Archer’s 68,300-square foot “Integrated Test Lab and Manufacturing Facilities” in San Jose, California.

15,000 battery packs per year are planned to be produced at Archer’s “Integrated Test Lab and Manufacturing Facilities” in San Jose, CA.

Archer was approved by CAEATFA for a sales and use tax exclusion with an estimated savings for Archer of ~$10M over the next few years

The construction of “ARC“, the roughly 400,000 square foot eVTOL aircraft manufacturing facility located on an 100 acre property in Covington, Georgia was recently completed in December 2024. It began construction in March 2, 2023.

Archer plans to produce around 650 eVTOL aircraft per year by 2030 at the “ARC” plant, but it can be expanded to double the size (800,000 square feet) increasing the manufacturing capability to 2,300 eVTOL aircraft per year.

What Archer and Palantir CEOs have to say:

“While the aviation industry has an unmatched level of safety, much of the legacy technology supporting the industry has only incrementally advanced. AI and software present an inflection point that will shape the future of aviation. We’re proud to be partnering with Dr. Karp and the entire Palantir team to build the AI backbone for the next-generation of aviation.” – Adam Goldstein, Founder and CEO of Archer Aviation

“Palantir’s partnership with Archer is redefining the future of flight, making it not only more efficient but also more accessible,….. By integrating Palantir’s advanced AI capabilities with Archer’s innovative approach to aircraft manufacturing and operations, we are setting the stage for a transformative leap in efficiency, safety and sustainability.” – Alex Karp, Palantir Co-founder and CEO

Palantir Foundry

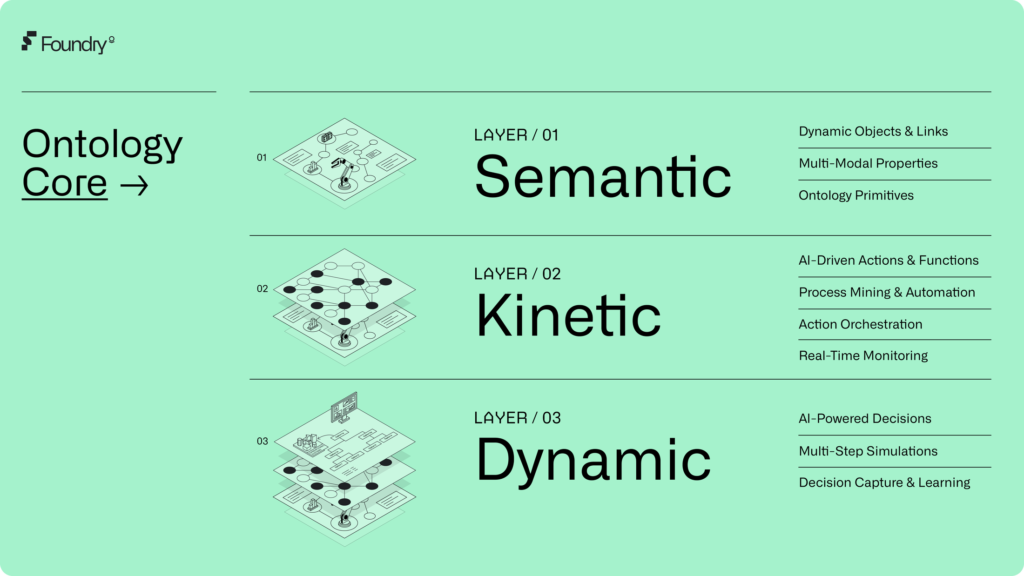

Palantir’s Foundry operating system uses ontology to organize data so that it can be optimally retrieved and utilized for complex decision making.

Per wikipedia: “In information science, an ontology encompasses a representation, formal naming, and definitions of the categories, properties, and relations between the concepts, data, or entities that pertain to one, many, or all domains of discourse.”

The 3 structural layers of Palantir’s Foundry Ontology core.

Once the data is processed through the Ontology Core, it can be accessed by the Data and Modeling Teams to use for their specific projects.

Palantir Foundry’s integration in the manufacturing and supply chain

Palantir AIP (Artificial Intelligence Platform)

With the data organized, managed and connected to the different teams, the other side of the equation is analyzing that data using AI in order to make predictions as well as to generate fast and efficient decisions in a fraction of the time.

Taking note from Stellantis

With Archer looking to its main partner, automotive conglomerate Stellantis for expertise in design, mass production, supply chain management, it should come as no surprise that Palantir has jumped on board to help with its Foundry operating system and AIP (Artificial Intelligence Platform). Stellantis has collaborated with Palantir since May 25, 2022, using Palantir’s Foundry to further increase the manufacturing efficiency across all of the 14 brands at Stellantis. Production speed, vehicle quality, supply chain performance, sales, and scale marketing being some of the key areas for improvement.

“We are grateful for the confidence of Stellantis that led to the expansion of our collaboration across their enterprise…. In today’s data-driven world, the Foundry operating system is uniquely positioned to offer insight into critical operational and manufacturing functions.” – Josh Harris, Executive Vice President at Palantir

A Peugeot assembly plant in Europe. Peugeot is one of 14 brands owned by Stellantis that has implemented Palantir’s AI in improving manufacturing efficiency.

Palantir’s Warp Speed and Panasonic’s “Smart Factory” initiative

Palantir is also no stranger to battery production. On June 7, 2023, Palantir’s Foundry by Panasonic Energy of North America (PENA) for Panasonic’s “Smart Factory” initiative. Foundry is used at its Gigafactory 1 plant in Sparks, Nevada, as well as at the new Panasonic factory in De Soto, Kansas factory which will become operational this year (2025). Panasonic is a supplier of batteries for Tesla Motor electric vehicles.

“We engaged Palantir to assist on our journey towards a connected factory by addressing the challenges of disparate data systems and manual work arounds leading to inaccurate data analysis…Within Foundry, we were able to operationalize our data and, within months, reduce waste throughout our manufacturing process. Over multiple use-cases across functional groups, Foundry is assisting in driving operational excellence for PENA, empowering our people through accurate data-driven decision making and delivering significant ROI per year. And we are just getting started.” – Justin Herman, Chief Information Officer of Panasonic Energy of North America (PENA)

“PENA is a leader in their field, and Foundry is the leading software to drive operational excellence for PENA….Foundry now serves as the foundation of PENA’s Smart Factory initiative, and we are already seeing meaningful impact on reducing material scrap and increasing line uptime, thereby improving the quality and volume of production outputs.” – Shyam Sankar, Palantir CTO

Panasonic is one of the few inaugural members in Palantir’s Warp Speed cohort, which include: Anduril Industries (which partners with Archer in military VTOL aircraft), L3Harris, and Shield AI.

According to Palantir, Warp Speed “is the manufacturing operating system that provides the speed, flexibility, and security required for the modern manufacturer. It is architected on the principle that software should adapt to the business, not the other way around. The inaugural cohort is already using the software to gain an advantage in dynamic production scheduling, engineering change management, automated visual inspection for quality, and more.”

On December 11, 2024 Palantir and Panasonic signed a 3 year agreement, as part of its extended partnership, in which Panasonic (PENA) will be able to “revolutionize American battery manufacturing” though the use of Palantir’s Foundry and AI. The goal is for Panasonic to help the United States have more stability against global supply chain disruptions, as well as be more energy self-sufficient through access to domestically produced electric batteries produced at Panasonic (PENA) factories in Nevada and Kansas.

“Warp Speed is enabling us to rapidly transform our manufacturing operation in Nevada and accelerate the ramp-up of our new factory in De Soto, Kansas……With our new facility, we are transforming a historical industrial site into a gigafactory that is creating advanced American manufacturing jobs and strengthening the domestic supply chain in a critical industry.” – Allan Swan, President, Panasonic Energy of North America

Palantir’s Foundry data management operating system will come in handy in helping Archer achieve the goal of producing up to 15,000 battery packs per year at Archer’s “Integrated Test Lab and Manufacturing Facilities” in San Jose, CA. These electric battery packs will power Archer’s Midnight eVTOL aircraft.

Anduril, Palantir’s Warp Speed, Palantir AIP, and Archer Defense

“Speed of delivery is everything for us…Warp Speed helps us ensure manufacturing capabilities for our customers quickly. By using the software, we’ve seen up to 200x efficiency gain in our ability to anticipate and respond to supply shortages.” – Tom Bosco, Chief Information Officer at Anduril

“At the dawn of WW2, we didn’t have a Defense Industrial Base, we had an American Industrial Base. This is also what our future must look like—America must reindustrialize and mobilize at warp speed to win….We are proud to support Anduril, Shield AI, L3Harris, and Panasonic Energy with best-in-class software to manufacture the critical products that underwrite our freedom and prosperity.” – Shyam Sankar, CTO of Palantir Technologies

On December 6, 2024 Anduril and Palantir announced the creation of a consortium to provide national security and military AI technology services “from the edge to the enterprise” for US government agencies and its strategic industrial partners.

Exabytes of data (an exabyte or EB is equivalent to quintillion bytes or 1,000 petabytes) from sensors of military hardware such as drones, vehicles and robots are essentially being lost since they are not actively being captured into data management systems.

This consortium between Anduril and Palantir seeks to address this issue through Anduril’s Lattice software system. Taking real-time data from the sensors of military hardware in the field, and transmitting it securely within a data mesh, such crucial data can be harnessed for AI training at government facilities.

The second issue deals with the harsh reality that no process exists on a large commercial scale to take such data and process it for AI purposes. Palantir’s AIP (Artificial Intelligence Platform) which has a “hyper-scale” capability, will by used by in this consortium, to provide the data processing required for AI training, including restricted and sensitive data related to Secure Compartmented Information (SCI) and Special Access Programs (SAP).

Palantir’s AIP (under this consortium with Anduril), will undoubtedly be used in the VTOL aircraft that are to be manufactured for the military by Archer Defense. Archer Defense has made an agreement with Anduril on December 12, 2024 (6 days after Palantir and Anduril announced their AI consortium) to manufacture hybrid VTOL aircraft for the US Department of Defense. $430 million was raised by Archer, from its long-time investors such as Stellantis, United Airlines, as well as new investors such as Wellington Management and 2PointZero (subsidiary of UAE based IHC).

Anduril was co-founded by Trae Stephens (a former employee of Palantir). Stephens and co-founder Palmer Luckey initially recruited employees from Palantir. Both the names Anduril and Palantir originate in the Lord of the Rings novels.

Skywise: Palantir and Airbus’ solution to large scale data analytics solution in the aviation industry

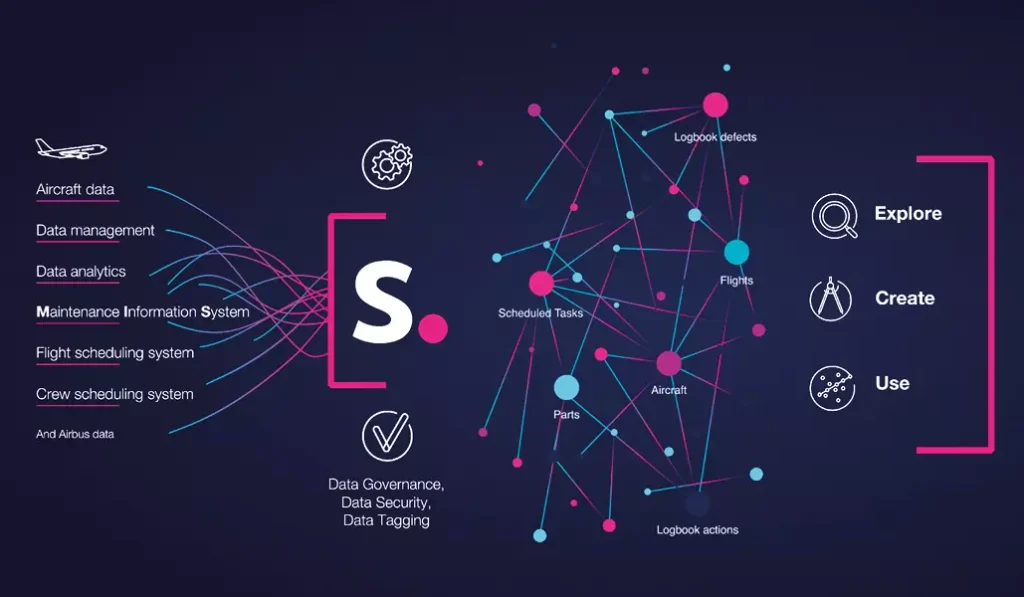

Palantir Foundry is no stranger in aviation. In 2015 Airbus saw Palantir Foundry’s potential in improving the efficiency in manufacturing of its A350 aircraft. Within the same year Airbus increased the delivery speed by 33%. In 2017 Palantir and Airbus created Skywise, which is a data analytics provider.

Skywise collects and analyzes aircraft data to predict optimized maintenance schedules, part lifespan, flight schedules, crew schedules, and many other relevant data driven decisions and planning.

Airbus was able to take the data and utilize it into providing better aircraft component design, fuel efficiency, passenger satisfaction, asset utilization, maintenance, and air & ground traffic control, in order to provide a better product and experience for all parties in the ecosystem. (diagram courtesy of Harvard Business Review)

Airbus boasts that over 11,700+ aircraft are linked using Skywise, with over 44,000+ users worldwide.

One of the major users of Skywise is United Airlines, which is an investor and partner with Archer Aviation in bringing the first commercial air-taxi service to Chicago O’Hare airport, as well as a major investor in Archer Defense.

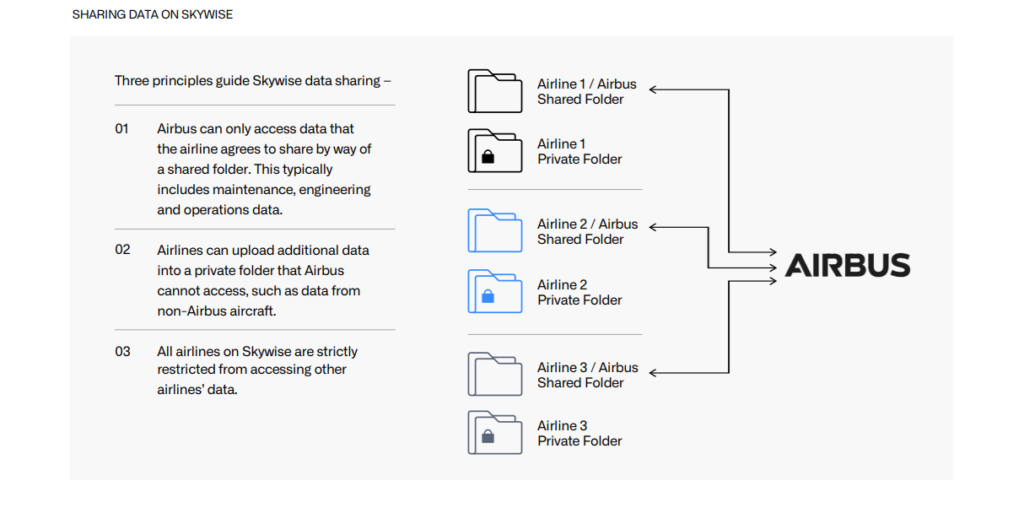

Summary of how the airline’s data is organized, shared with Airbus, or restricted from access

Petabytes of data (millions of gigabytes) from the thousands of sensor systems on Airbus aircraft are collected to identify any manufacturing defects, estimate component lifespan, measure airworthiness. Airbus claims that third-party analysis calculated Skywise provides a cost savings of greater than $1.7 billion per year and a revenue opportunity of $850 million per year.

“We see a 10% to 20% time saved with the use of Skywise Core. We are not working from quite a few disparate data sources, we are working from one single source […] improving the quality of the work that comes out.” – Jim Jackson Predictive Technologies Engineering at Delta Airlines

“Thanks to Skywise Predictive Maintenance we have avoided 35 technical cancellations in the month of August 2022.” – Swaran Sidhu Head of Fleet Technical Management easyJet

“The main value that we have seen in Skywise is in automating and standardizing how we calculate our KPIs and getting a single source of truth through the platform. We’re seeing value in the preventive app that we have developed with Skywise, with 10% improvement in the delays that we used to handle. 90% of the use cases that we have are solved by basic users. With Skywise, it’s very easy to get connected to different data sources and to our different data platforms, and it’s very flexible.”- Manager, Digital Transformation Team LATAM Airlines Group

Outlook for Archer Aviation

With the success already proven from Palantir’s collaboration with Airbus in developing Skywise, this new partnership between Archer and Palantir will take Archer Aviation to the scalability, efficiency in the supply and product chain, cost savings, as well as the safety level required for a rapidly growing eVTOL manufacturer. Archer’s embrace of Palantir developed AI solutions will lead to goals and milestones being accomplished in a shorter time frame without compromising on safety and quality. Rather, using such technology, safety and quality will be enhanced through risk minimization, identifying safety and quality control issues faster and addressing them before problems occur. As has been done at Panasonic (PENA) with their “Smart Factory” initiative, Palantir can assist Archer with the data analytics to achieve electric battery production levels necessary to meet the needs of their Midnight eVTOL aircraft. Finally, with Stellantis (a major partner and investor in Archer), which provides the mass production, design, and part supplier network resources critical for Archer’s quest for high volume production, already using Palantir’s data solutions, it makes perfect sense why Archer would want to join the Palantir ecosystem. We at VTOL buzz look forward to the data that will be released by Archer and Palantir in the near future, showing the cost savings and other manufacturing feats that were only possible thanks to Palantir’s AI ecosystem.

More Info:

Palantir’s Foundry platform: click here

Palantir’s AIP platform: click here

Palantir & Airbus Partnership Overview: click here

Official Press Release about partnership between Palantir and Archer Aviation: click here

Archer’s “ARC” Covington Georgia manufacturing plant: click here

Stellantis and Palantir partnership: click here

Palantir and Panasonic Warp Speed collaboration: click here

Palantir and Panasonic Foundry “Smart Factory” partnership: click here

California Alternative Energy and Advanced Transportation Financing Authority (CAEATFA) approval of Archer’s Sales and Use Tax Exclusion: click here

Anduril and Palantir agreement: click here

Archer and Anduril partnership: click here

The integration of Palantir Foundry in manufacturing and supply chain operations seems highly efficient. By organizing and connecting data across teams, it enables better decision-making. The use of AI for predictions and analysis is a game-changer in speeding up processes. This approach could significantly reduce operational delays. How does this system handle real-time data updates?

This is an interesting breakdown of how Palantir’s Foundry Ontology Core works, especially in manufacturing and supply chain contexts. The idea of organizing and connecting data for different teams seems like a game-changer for efficiency. I’m curious about how the AI-driven predictions are validated for accuracy—do they rely on historical data or real-time inputs? The potential for faster decision-making is impressive, but I wonder if there are any challenges in ensuring data quality across teams. How does Palantir handle potential biases in the AI models? Overall, it seems like a powerful tool, but I’d love to hear more about its limitations or areas for improvement. What’s your take on its scalability for smaller industries?

This is an interesting breakdown of how Palantir’s Foundry Ontology Core works. I appreciate how it emphasizes the importance of organized data for teams to leverage in their projects. The integration of AI for predictive analysis in manufacturing and supply chains seems like a game-changer. It’s impressive how it can speed up decision-making processes. I wonder, though, how accessible this system is for smaller companies with limited resources. Do you think the benefits outweigh the potential costs of implementation? Also, how does Palantir ensure data security and accuracy in such a complex system? I’d love to hear more about real-world applications and success stories. What’s your take on its scalability across different industries?

The integration of Palantir Foundry in manufacturing and supply chain seems like a game-changer. The way it organizes and connects data across teams is impressive, especially with AI-driven analysis for faster decision-making. I wonder how it handles real-time data processing in such complex environments. The Ontology Core’s role in structuring data for specific projects is intriguing—does it adapt to different industries seamlessly? I’d love to know more about the challenges faced during implementation. How does it ensure data security while maintaining accessibility? Overall, this approach could revolutionize efficiency, but I’m curious about the learning curve for teams adopting it. What’s your experience with Foundry in similar setups?